Manufacturing

MVP has invested in quality machinery that equips us with the ability to meet a wide range of customers’ needs. Our specialized equipment allows us to manufacture products that many of our competitors cannot. We continue to make these investments because it saves our customers time and money and helps ensure quality.

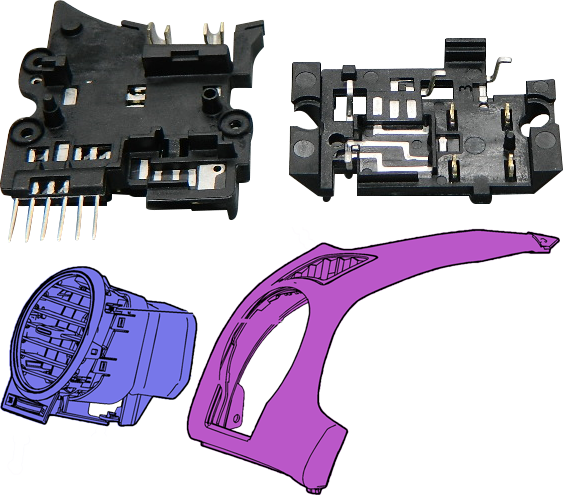

Injection Molding

- Horizontal

- Vertical

- Two Shot

- Insert

- Gas Assist

Decorating & Assembly

- Hot Stamping

- Chrome Plating

- Painting

- Pad Printing

- Ultrasonic Welding

- In-Mold Labeling

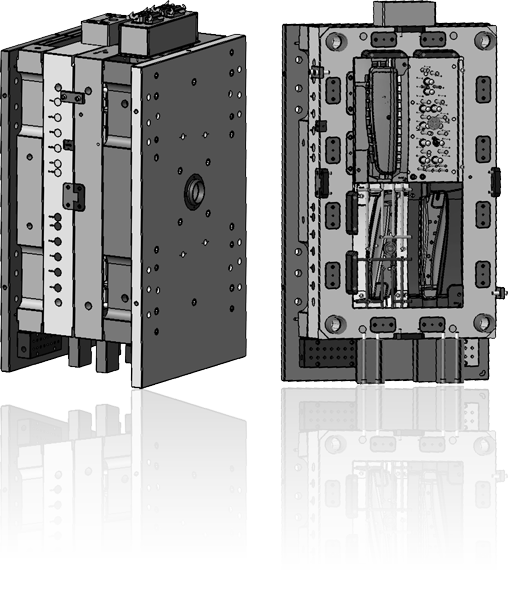

TOOLING & TOOL SOURCING

MVP Plastics offers mold flow analysis to guide production and assure functionality and manufacturability. We engage our customers early on to determine what is and is not feasible for manufacturing through our expert guidance during the analysis.

MVP offers a broad spectrum of materials to work with through the utilization of thermoplastics resins including but not limited to:

- ABS

- Acetyl

- PC

- PC/ABS

- PP

- Nylon

- TPE

We have the capacity through our deep global network to provide domestic and low cost country tooling sourcing. Our flexibility provides a bottom line price benefit to our customers.

ENGINEERING & PRODUCT DESIGN

Program Management

MVP takes a hands-on approach to engineering, employing processes that design highly capable parts. MVP utilizes both our vast experience and Finite Element Analysis (FEA) tools to provide our customer with a highest level of confidence before cutting steel.

Our Program Management is centered around Advanced Product Quality Planning (APQP) and Design for Manufacturing (DFM)

Prototyping:

MVP Plastics can provide functional and nonfunctional engineering samples based on the customer’s needs. Parts can be created in a number of forms that include 3D Printing, urethane, aluminum, and low volume production tools.

CAD Software options:

Our CAD capabilities allow us to read all forms of native files. Customers can send math or prints (Catia, Unigraphics, IGES, Autocad, STEP, Solid Works).